Best Kept Secret to Screw Anchor Installation

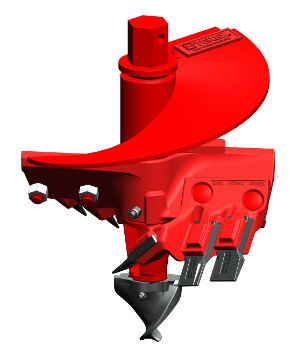

What’s a digger derrick without efficient tools? The Hollow Kelly Bar is another example of why Terex Utilities designs and manufactures its own auger tooling. It’s actually one of the best kept secrets for screw anchor installation.

Terex Utilities recently released a video that demonstrates how distribution crews can more easily install screw anchors. By using the Terex Utilities Hollow Kelly Bar instead of traditional locking dog and square bars, digger derrick operators can shave minutes off the process, with less manual handling for every screw anchor that needs to be installed.

Quality by Design

Terex Utilities’ design combines the auger extension shaft and screw anchor drive. The screw anchor rod inserts directly into the hollow Kelly Bar, eliminating the need for a screw anchor adaptor on the digger derrick. This helps eliminate manual handling, improves safety through less lifting, and increases productivity.

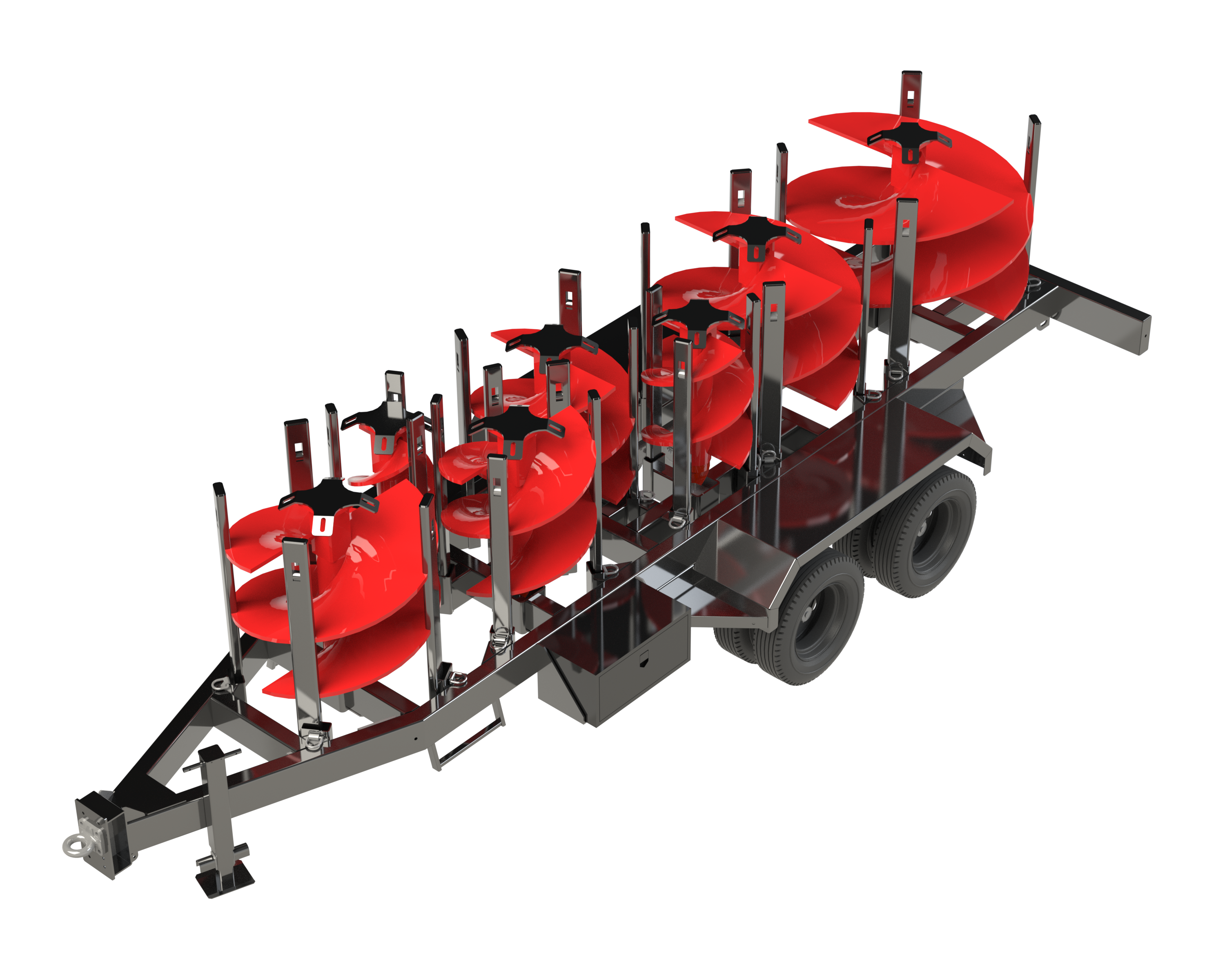

Less Lifting + Dual Purpose = More Productivity

In a side-by-side comparison, Terex Utilities shows how the process takes only about 35 seconds using the Hollow Kelly Bar versus 2-1/2 minutes with the heavier locking dog and square bar once the auger is removed.

In addition, the Hollow Kelly Bar with spring-loaded cam action continues to be used as the auger extension shaft, making it just as easy to switch from digging a hole at increased depth, then setting screw anchors before moving to the next pole. In situations where multiple utility poles are being installed, productivity is dramatically improved.

Equally important, is how much less manual handling is needed. The square bar can weigh as much as 58 lbs and the locking dog can weigh as much as 36 lbs in a traditional setup. By eliminating that you are reducing risk of musculoskeletal injuries.

For more information – or to request a quote – click here.